We partner with developers and OEMs

About our productThe Cleanfix reversible fan gives machine developers and OEMs a clear competitive advantage

By installing a Cleanfix reversible fan in your machine, you ensure that the engine is cooled effectively by the fresh air that flows in. In cleaning mode, the Cleanfix reversible fan blows the radiator free of contamination in a matter of seconds. As a result, your machine runs longer, requires less maintenance and works more efficiently.

Partnering with developers and OEMs, we offer powerful reversible fans and support you in developing your own individual solutions.

Make the most of our experience, our system expertise, and, last but not least, our sophisticated technical options to incorporate the Cleanfix reversible fan – one of the most sustainable and powerful cooling systems on the market – into your machine designs.

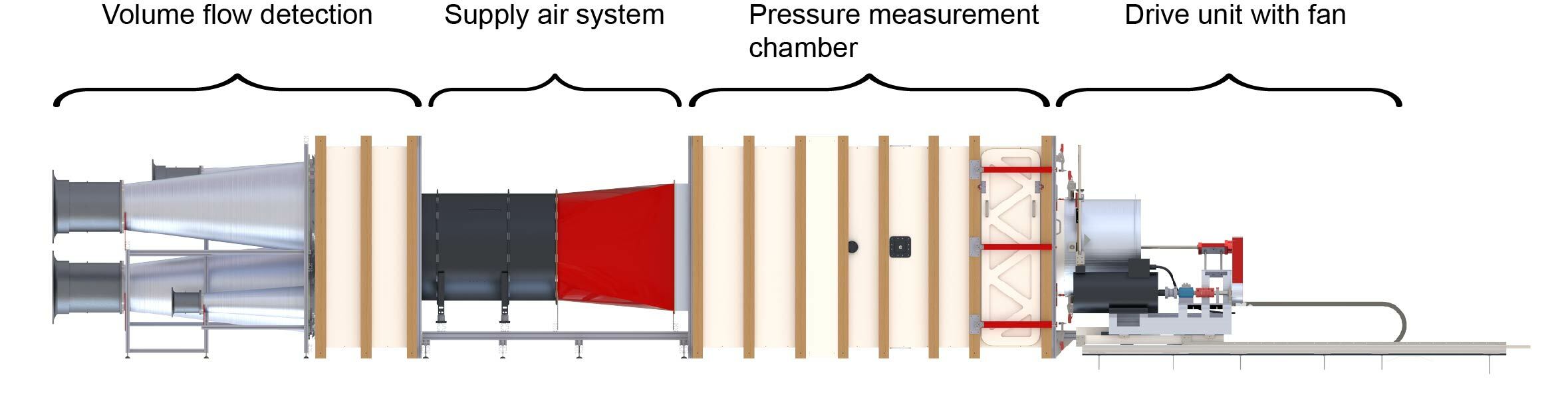

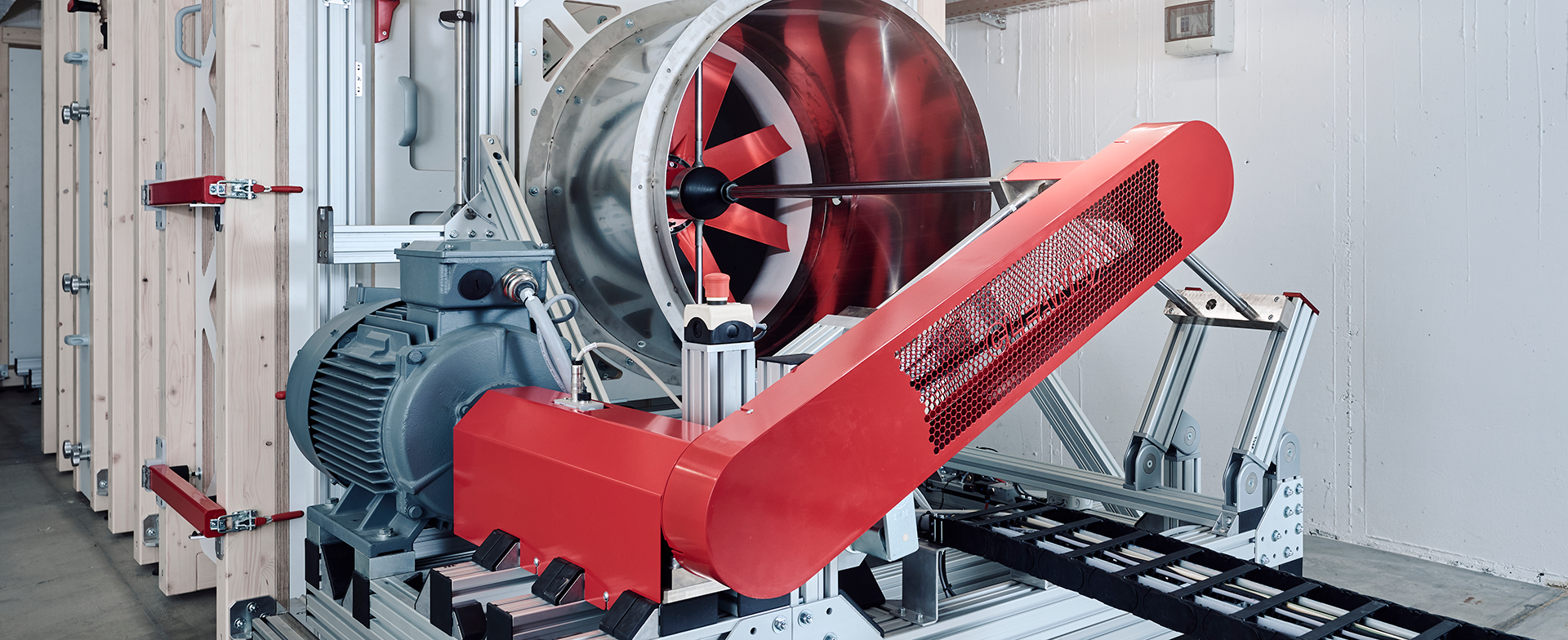

Working together, we’ll use the new test rig

to determine the precise efficiency of your quiet, energy-efficient radiator modules

The test rig is suitable for measuring not just fans and radiator packages but models too. This will significantly reduce your development costs, as the test rig can also provide very informative drag characteristic curves for new developments generated in the form of a scaled-down 3D print.

The standard-compliant suction-side test chamber is 14 m long, complies with international standards (e.g., ISO 5801 and ANSI/AMCA 210-16) and is suitable for axial fans with an impeller diameter of 300 mm to 900 mm.

Would you like to find out how you can implement the innovative reversible fan in your individual machine design? Then don’t hesitate to get in touch!

ContactWe have efficient ways of testing your design, the material

and the respective parameters even before the first prototype is developed.

This will get your machine to the market more quickly and improve its positioning.

We are constantly improving our materials in our laboratory. As such, we can examine material pairs and surface finishes as well as changes to the materials before and after testing in the test facility.

In our 3D printing room, we also create scaled-down development models, e.g., new blade profiles for your individual machines, so that they can be tested in our test chamber.

Our engineers look forward to helping you develop your project.

Contact us now and we’ll work with you to develop the perfect solution.